Success Story

Success Stories - Precision Metal Components & Plastic Mold

TaiYou prides itself on meeting the needs of its customers with our expertise & capabilities in metal components, tooling. The success stories of our clients are proof of the value we deliver. Here are just a few examples of the quality products and value added services that we deliver every day.

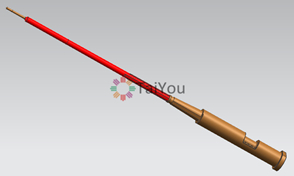

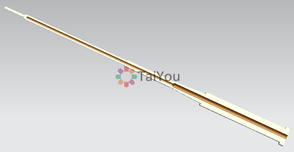

Medical Device Component

Perfect Results were Gotten

We conquered all the challenges on the technology, delivered several batchs of goods to the customer.

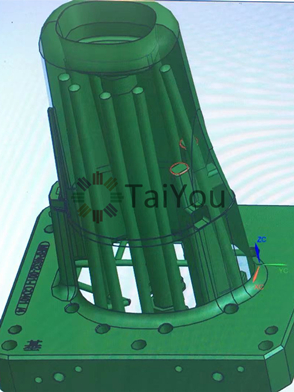

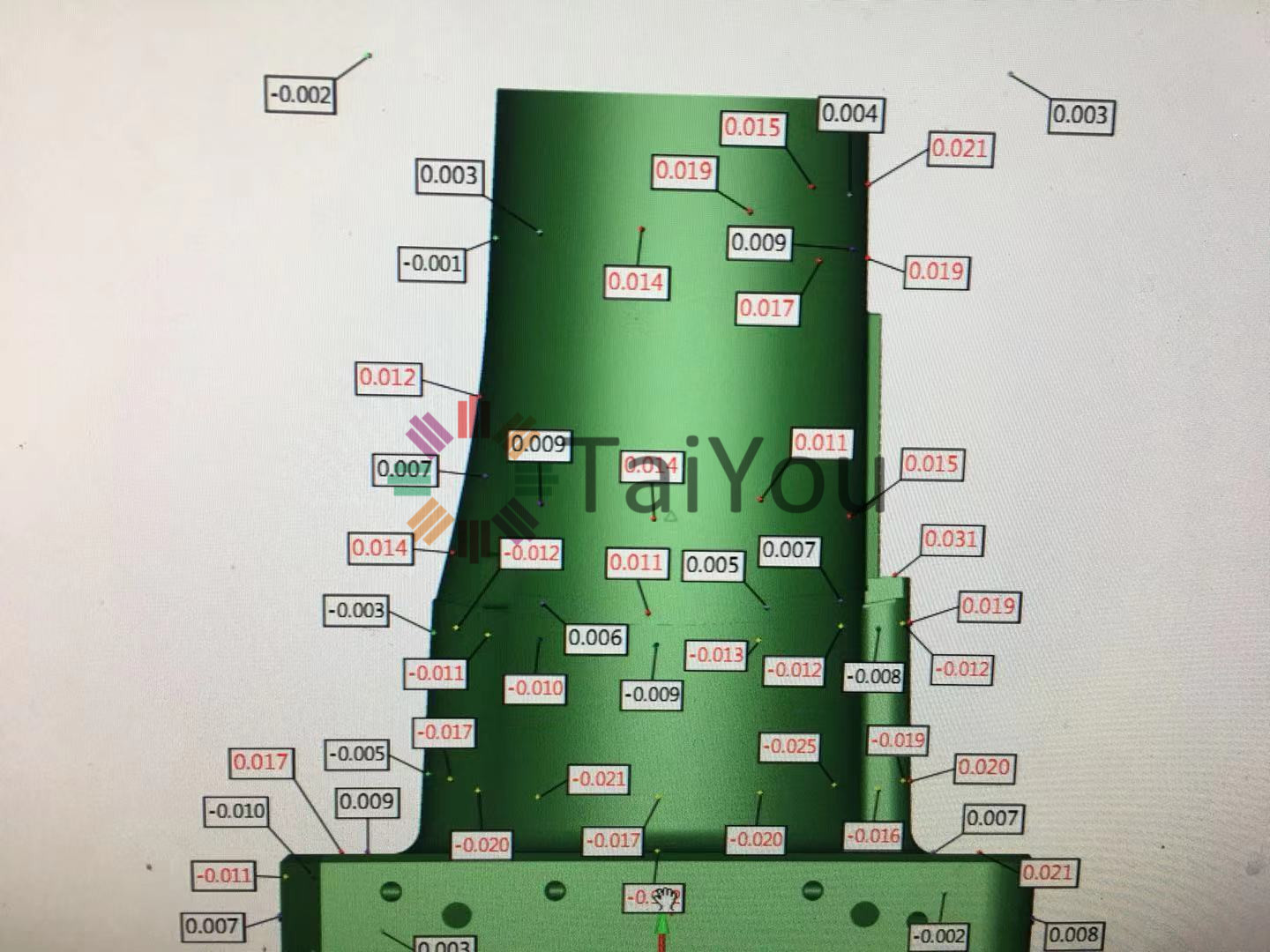

Core Manufacturing

For raw material, each core weight is 340kg, approximately 5 human beings weight, its dimension is 280x350x432 mm. There are 4 cores in one set of tooling. The customer paid order for 2 sets of tooling, and asked no any welding, surface SPI-A1 high polishing. The material is AssAB DIEVAR, hardness HRC48-52. Because the material value is very high, it's impossible to cut backup material to build together. We cut 8 pieces of raw material to build 8 cores, no any mistake happened in the manufacturing processing, delivered 8 pieces of quality core to the customer on time. The customer was very satisfied with our manufacturing.

)

Get Help with

Your Next Project

Taiyou Precision is a high precision components and plastic mold manufacturer.

Tell us what help you need with your precision components, Core/Cavity, plastic mold project.